One of the core principles of lean manufacturing is optimising available space. By optimizing the use of space in the workplace, businesses can drive continuous improvement and gain a competitive edge. This could take the form of designing production facilities that are organized and efficient, with an emphasis on reducing wasted space and minimizing the movement of people and materials. Making small 6S improvements on the factory floor or in an office space could save a great deal of time when carrying out day to day activities within the workplace.

Optimising space in the workplace can lead to a whole host of benefits for a businesses. Businesses become more efficient and increase their productivity. There is also a decrease in accidents and an overall increase in safety. On top of all this, lean space optimisation can improve employee satisfaction and morale. A well organised workspace can improve job satisfaction and reduce stress. This, in turn, can lead to higher employee retention and better overall performance.

See below for some of the material handling solutions we offer that are a part of our standard offerings. These solutions help optimise storage space and reduce the need for excess inventory, while also increasing picking time.

Material Handling Solutions

Material handling solutions play a critical role in lean space optimization by improving the flow of materials and minimizing waste in manufacturing and warehouse operations. They also increase picking times which in turn increases overall efficiency.

Conveyors

Made with a FlowTube stainless steel frame, our bespoke conveyor system increases productivity, safety, & ergonomics, as well as improving material flow and utilisation of floorspace. This unit has stainless steel plate castor wheels to allow the operator to move the conveyor around the factory floor, making most efficient use of the space.

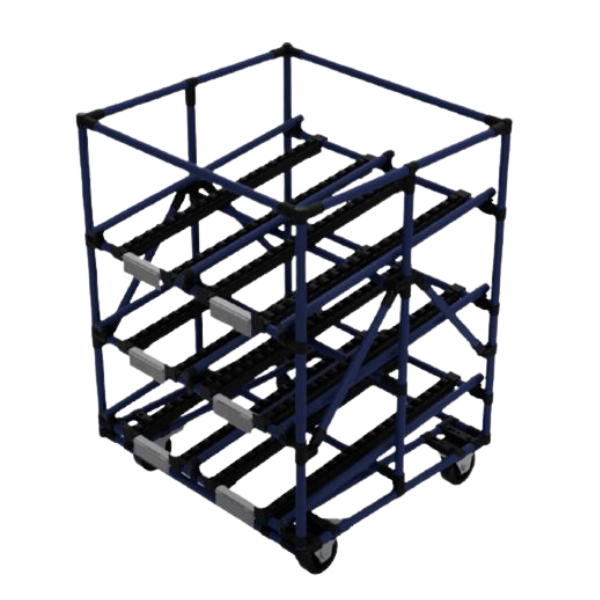

Racks

Our rack range allow goods to be packed more compactly to help free up extra floor space on the factory floor and can help in keeping stock handling to a minimum. This rack was made with a 28mm bluetube FlowTube frame and zinc plate castors.

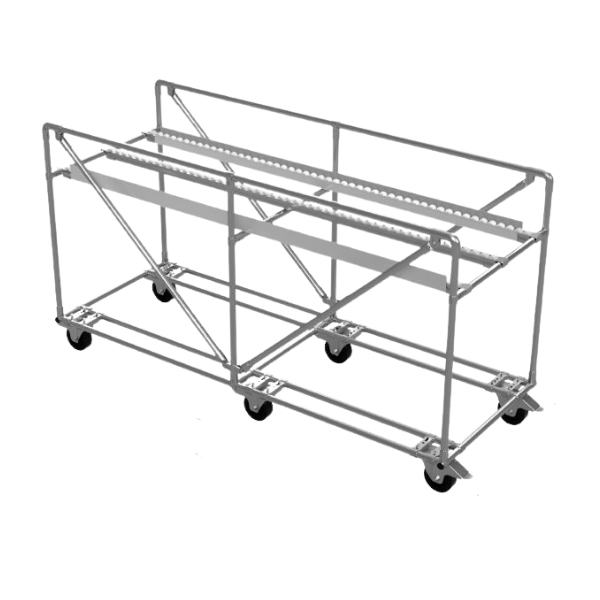

Trolleys

Our trolley range offer an incredibly practical material handling solution for transporting both light and heavy items. They increase warehouse efficiency by allowing employees to quickly, safely and efficiently load, transport and locate items in the warehouse. This trolley was made with a 28mm FlowTube ESD frame and ESD plate castors.