Products that might interst you

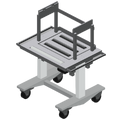

This Height Adjustable Basket Jig Trolley was made for a customer in the medical device sector. It is an ergonomically designed unit to allow the operator to make the most efficient use of the trolley’s footprint. The basket on the trolley was designed to protect the items within it and act as a tolerance gauge for the basket fixture. A Poka Yoke system to lock the customer’s basket into position was also developed to ensure safe operation.

This was made with LINAK height adjustable components and actuators. The height adjustable movement on the operating surface and basket incorporates a four way control system (up and down directions for table and basket). This unit is also fitted with a rechargeable battery for energy optimisation. This was a one-off, bespoke product.

Get a real sense of what you are buying!

Our tools allow you to get the best sense of what we offer. From a 3D and AR viewer to the products’ drawings, we want to make sure we have every base covered.

*Augmented reality experience is currently supported on the following devices: iPhone on iOS 12 and Android 8.0with ARCore 1.9 support.

View Product in AR

Scan the QR Code with your phone to see the product in Augmented Reality or if you’re already on your phone click here.

See the drawings

Get all the measurements you need!

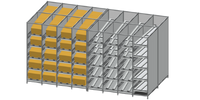

This assembly workstation was made for a multinational automotive customer. They had a requirement for a sub-assembly station with 30 different components required for assembly. The customer’s key goal was to ensure 100% quality throughput with ergonomic improvements to ensure positive operator experience. Flow of product and layout was integral to ensure output efficiencies to meet their customer expectations. This workstation was build using ESD FlowTube components to suit the customers’ environment and product build.

View Product in AR

Scan the QR Code with your phone to see the product in Augmented Reality or if you’re already on your phone click here.

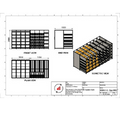

This product, for a multinational company in the medical device sector, is still in its design stage. The customer is looking for a solution to manage multiple and varied inventory components at one point of use. This FIFO rack will cater for 40 different types of product as well as a return lane for the empty totes which supports the customers internal Kanban system.

The unique design allows for greater flexibility, accuracy and control of product for this customer’s production operations. The rack is being designed using aluminium FlowTube profile to suit this customers work environment.