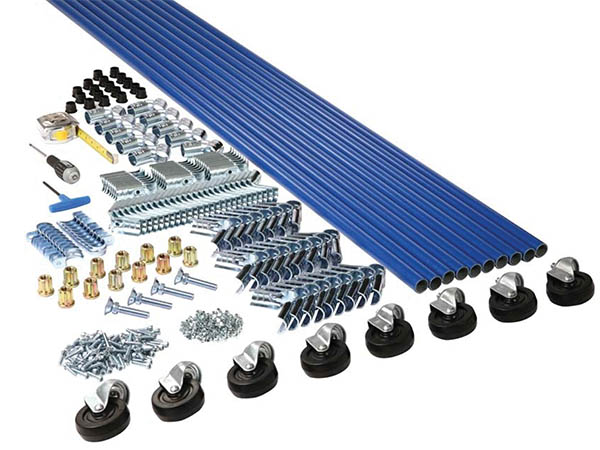

Modular Tubing, Profile, Fittings & Components

Build Flexible, Reusable Manufacturing and Storage Solutions with FlowTube

Looking for modular tubing, brackets and fittings to build your own workstations, trolleys or material flow systems? FlowTube is a proven modular tube and joint system used in manufacturing, assembly, warehousing and clean environments to improve flow, productivity and space utilisation.

Why Choose FlowTube Modular Tubing Systems

FlowTube is designed for businesses that need adaptable, durable and cost-effective solutions without welding or specialist fabrication.

Key benefits:

• Improves productivity and workflow

• Fully reusable and reconfigurable as processes change

• Fast, simple assembly with minimal tools

• Modular and standardised for better control

• High aesthetic finish for production and clean environments

• Space-saving designs for compact layouts

• Virtually maintenance-free

• No specialist skills required, just a tape measure, tube cutter and 5mm Allen key

• Hard-wearing steel with internal rust inhibitor for long service life

• Oxidation-resistant materials including stainless steel and nickel finishes

• Non-porous, non-shedding surfaces, easy to clean

• Environmentally responsible through reuse and long life

• Bespoke solutions without the cost of traditional welded fabrication or cleanroom systems

What Is FlowTube

FlowTube is a modular system of reusable steel or aluminium tubes combined with rapid-assembly joints, brackets, roller tracks and accessories. The system allows you to design and build custom structures using a building-block approach that supports Lean Manufacturing, Kaizen and Continuous Improvement.

Structures are assembled, not welded. This allows layouts to be modified, expanded or reused as production requirements change, protecting your investment and reducing waste.

ATC works with FlowStore, the UK distributor for FlowTube, combining local Irish engineering support with UK-based distribution and assembly capability.

Applications for FlowTube Modular Systems

FlowTube is used across a wide range of industrial and manufacturing applications, including:

• Assembly and production lines

• Cell feed and material flow systems

• Industrial shelving and storage

• Carts, trucks and trolleys

• Ergonomic workstations and benches

• Packing and kitting stations

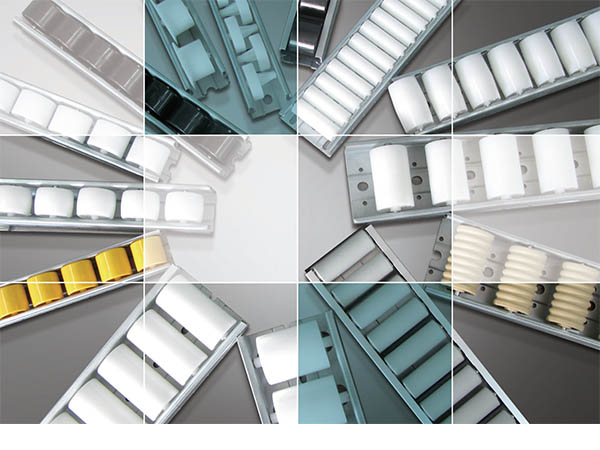

• FIFO racks and conveyors

• Display stands and visual management boards

• Safety signage and notice boards

• Customised structures for manufacturing, distribution and logistics

Solutions can be designed to suit light or heavy-duty weight requirements.

Support from ATC

ATC can support you at any stage:

• Design and layout planning

• 3D concepts and diagrams

• Full supply and build

You choose the level of involvement. The system remains simple, flexible and cost-effective.

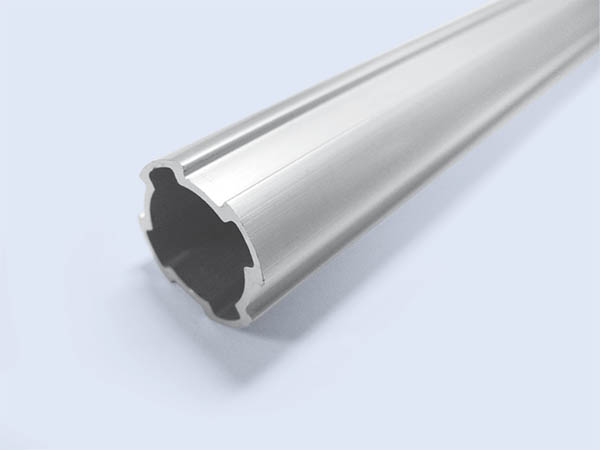

Tube Specifications

Tube diameter:

28mm

Standard stock length:

4000mm

Materials and finishes:

• Powder-coated steel

• Stainless steel

• ESD-safe options available

Available tube colours:

Ivory, dark blue, grey, black, red, white, ESD black and stainless steel.

Other colours available on request.

Metal Joint Specifications

Available finishes:

• Black coating

• Black zinc plating

• White zinc plating

• Nickel plating

• Ivory powder coating

• Grey powder coating

• Blue powder coating

Frequent Questions

Modular systems like FlowTube enable flexible, quick-to-assemble solutions that can be easily adapted or expanded. They support continuous improvement practices, reduce waste, save time and money, and improve overall efficiency in manufacturing and storage environments.

FlowTube's simple, reusable, and flexible design aligns with Lean Manufacturing and Kaizen principles by simplifying processes, encouraging continuous improvement, reducing waste, and increasing productivity through easy customisation and quick assembly.

FlowTube is a modular, reusable tube system with connectors, brackets, and accessories designed for material flow solutions. It allows quick assembly of storage, workspace, and manufacturing structures that can be customised to meet various industry needs.

Yes, FlowTube solutions can be designed to meet any weight requirement, thanks to different tube thickness options and customizable components, making it suitable for a wide range of industrial applications.

FlowTube components come in various finishes including stainless steel, colour-coded plastic coatings, black zinc, white zinc, nickel plating, and powder coatings in multiple colours like ivory, blue, grey, black, red, and white.

Yes aluminium square profile is available too.

FlowTube structures are assembled using quick-connecting joints and brackets without welding. The system is designed for rapid, tool-free assembly, making it easy to create and modify solutions as needed.

Contact Us

We’re always happy to provide you with whatever assistance you may need, so please feel free to reach out to let us know how we can help.

Unit 98/99,

Shannon Industrial Estate,

Shannon,

Co. Clare,

V14 W242,

Ireland

T: +353-61-708140 info@atcgroup.ie

Enterprise Ireland Lean Service Provider