Industry 4.0 Automated Guided Vehicles Trolleys & Integration Applications

With the ever-reducing cost of very smart AGV units, the tedious work of correctly replenishing an assembly station is made fast and simple.

This is just one of the ways in which ATC and the FlowTube range of reconfigurable modules offer the ideal platform for industries gearing towards industry 4.0 solutions to improve efficiency and profitability.

Benefits include:

- Improved plant logistics.

- Controlled transfer of product

- Improved safety.

- Reduction in defect material.

- Improved inventory management.

- Lightweight Alum Solutions increase AGV battery life.

Within Industry 4.0 initiatives, the use of AGV systems (Automatic Guided Vehicles) has seen a dramatic increase, as simple manual handling becomes progressively replaced by automation techniques.

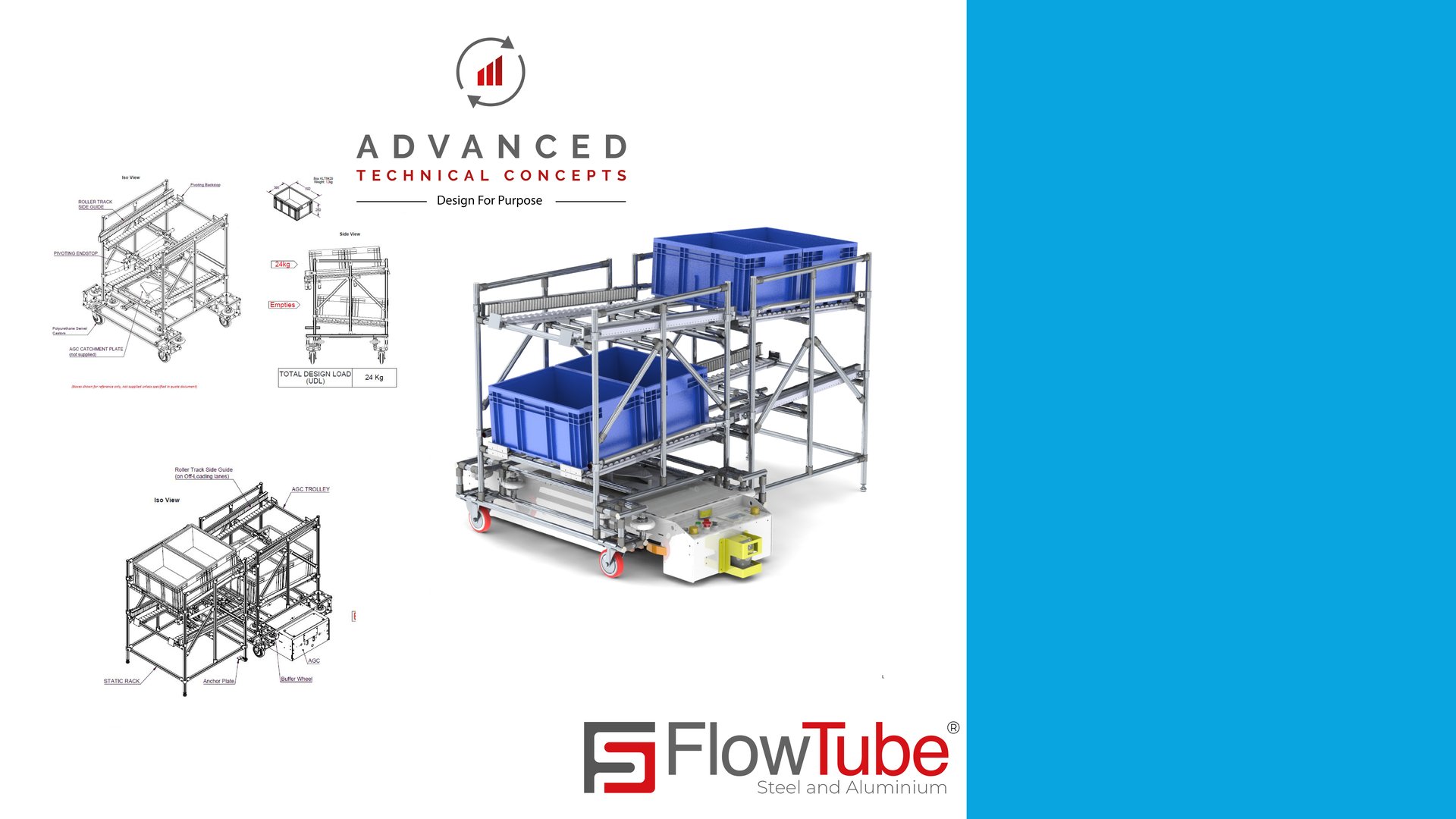

ATC works as a partner in these smart factory applications, providing auto-load/un-load rack/trolley units (both AGV-mounted and manual). These are sometimes referred to as ‘shooter racks’.

Highlighted in the images and video line is a trolley carried by an AGV to the desired location, where it engages with a matching line-side rack. The act of engagement releases the new containers to flow into the line-side rack in a single movement. At the same time, empty containers from the assembly rack are released and flow by themselves into the AGV trolley.

Here the manual loading, one by one, of full containers of new parts for assembly into a line-side flow rack, is replaced by a partly mechanised interface trolley.

Frequent Questions

AGVs, or Automated Guided Vehicles, are mobile robots used to transport materials automatically within factories, playing a key role in Industry 4.0 by enabling smarter, more automated manufacturing processes.

Automation enhances efficiency, reduces manual labor, minimizes errors, and increases productivity, which are essential for competitiveness and adapting to Industry 4.0 standards.

The page explains how ATC's AGV systems and reconfigurable modules support Industry 4.0 by automating material handling, such as loading and unloading containers with trolley units that engage with line-side racks for efficient flow.

AGVs replace manual handling with automation, allowing containers to be moved seamlessly between racks, reducing manual labor, increasing efficiency, and supporting smart factory operations.

ATC offers auto-load/unload rack and trolley units, including AGV-mounted and manual options, designed to integrate with Industry 4.0 initiatives for improved productivity and automation.

'Shooter racks' refer to line-side racks that work with AGV-mounted or manual trolley units to facilitate quick loading and unloading of containers, streamlining material flow in automated systems.

Do you need advice about material handling solutions for your needs?

Our team will work with you to determine the best solution to suit your needs. Fill in the form and our specialists will contact you as soon as possible.

Unit 98/99,

Shannon Industrial Estate,

Shannon,

Co. Clare,

V14 W242,

Ireland

T: +353-61-708140 info@atcgroup.ie

Enterprise Ireland Lean Service Provider